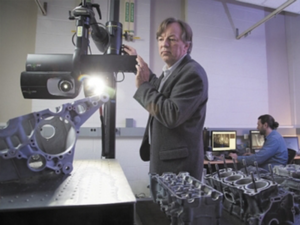

East Hartford’s Bolton Works relies on technology for generating three-dimensional images that has allowed manufacturers to churn out countless parts made to minutely precise tolerances or specifications. Called metrology, Bolton Works uses 3-D scanners to carry out precision checks on jet-engine parts for East Hartford’s Pratt & Whitney, and on manufactured components from other commercial-industrial customers. “Anything that’s manufactured needs to be inspected at some point,” said Mark Bliek, founder and president of the three-person shop housed in a small corner of the Connecticut Center for Advanced Technology on Pratt & Whitney’s campus. “You need to know it meets your design intent.” But 3-D scanning, as Bliek has long known and a cadre of UConn engineering pupils have learned, also can be invaluable for reverse-engineering parts and components — while generating new revenue-producing business opportunities. Since 2014, UConn students have tapped Bolton Works’ 3-D scanning expertise to produce a more powerful motorcycle engine to propel their lightweight, open-wheel race car into an annual international competition that challenges college pupils to design, develop and race a Formula-style race car. The latest Society of Automotive Engineers annual Formula SAE competition, as the race is known, will feature some 119 college teams — including UConn — May 10-14, at Michigan International Speedway. In addition to helping local students, Bliek says his shop’s work for UConn in the Formula SAE challenge has exposed Bolton Works’ technology and talent to a wider audience — in Connecticut and across the U.S. and the world. Indeed, demand and backlog for Bliek’s services, he said, have prompted him to search for larger quarters, around 3,000 to 4,000 square feet, for his company.